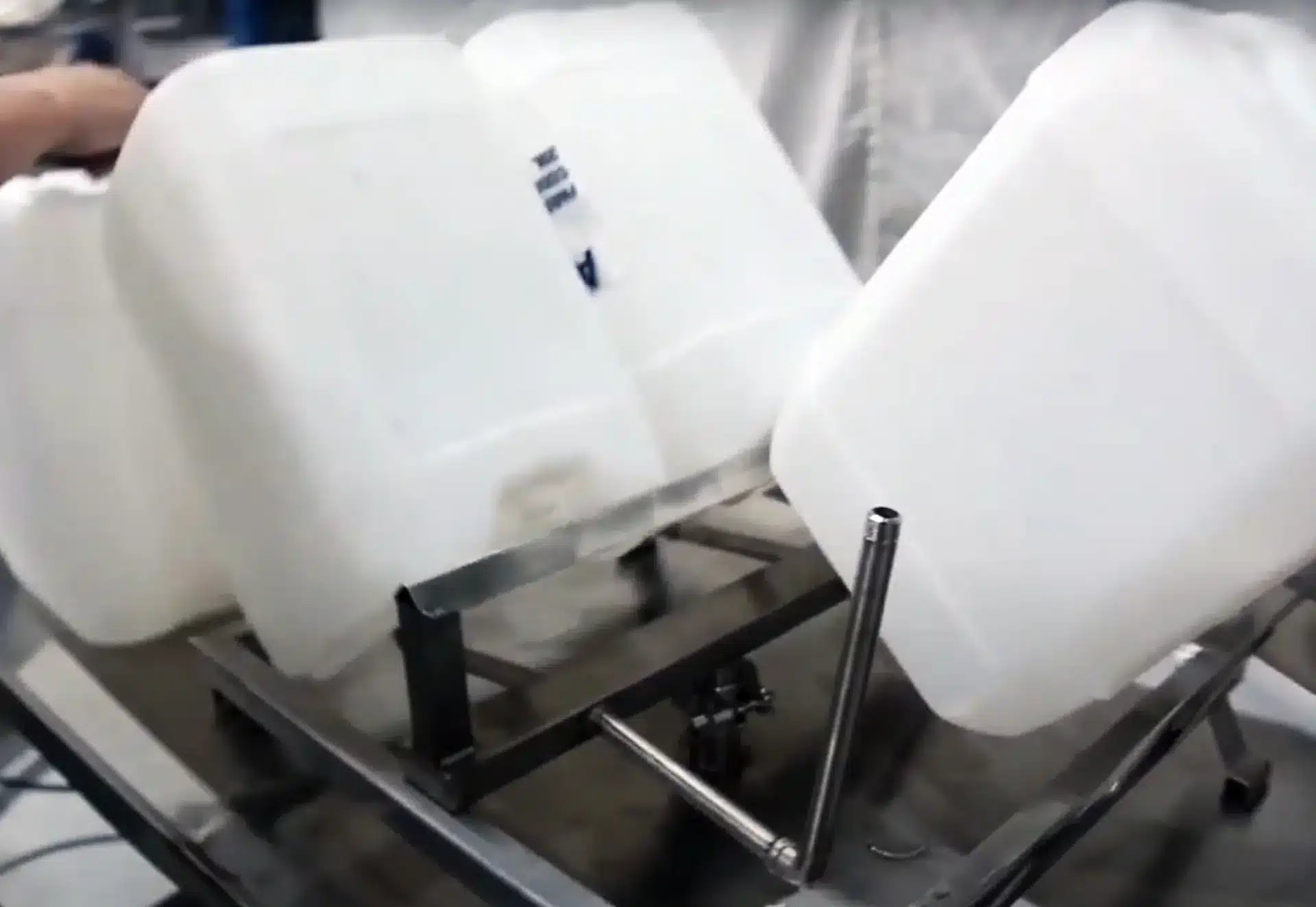

Multi-Functional Dryer A machine built for drying bottles

Simplify your drying process

Fed up wasting a lot of time drying bottles and containers? Want to speed-up the bottle drying process? Here is a solution for you. We offer a multi-functional dryer that can dry the large-volumes of glass, stainless steel, and plastic bottles very quickly.

Here is why our Industrial Container Washer is a favorite for dairy farms, brewers, winemakers and other producers who use large containers every day :

- High speed and high impact air flow

- Easily customizable to fit different types of bottles

- Fully automated drying functions

- The multifunction dryer can be customized to fit any type of bottle or container.

We have designed a unique, efficient and versatile bottle dryer. Its available on the market today. The bottle dryer allows rapid evaporation and a large production volume.

Do you want to speed up your drying process?

Optimize your bottle drying with the multifunction bottle dryer

The multifunctional dryer will be fully automated for your activities. It dries the glass, Stainless steel as well as plastic.

Aquatech-BM is the industry leader in washing, cleaning and drying machines for all container sizes. With its ease of use, this multifunction dryer allows rapid evaporation and an impressive production volume. After washing and disinfecting your containers, the goal is to achieve rapid drying. The temperature and the duration of the drying have an impact on the result and these variants are easily configurable, all being linked to the desired functionalities. It’s simple, if you want to program your cycles yourself, opt for the touch screen.

Thanks to its high speed as well as high impact air flow, the Aquatech-BM dryer can completely remove any liquids that may have remained after a washing and / or rinsing operation. The nozzles are designed to be tested to remove moisture and liquid residue before your filling operation. Centrifugal air is used to feed the Aquatech-BM bottle dryer. Drying is done with the necessary pressure for the inside and outside of your containers. It comes with the air diffuser and interchangeable baskets corresponding to the diameter of your containers to simplify installation.

Move your productivity to the next level

Large load capacity adapted with your choice of wash cycle programming

Typical cycle; Soap wash, Disinfectant washing, final rinse with heated water around 200 °F / 93 °C.

Programmable according to the parameters required for the desired cleanliness.

1 or 3 phases

230-240 vac, 1ph 50/60 Hz 30 amp,

400 vac, 3ph 50/60 Hz 30 amp, + neutral or 208 vac 3ph 50/60 Hz 30 amp,

Width: 41 ⅞’’ inside (106.36 cm); Depth: 40 ¼’’ ; Height: 73 3/16’’ Weight, 185 lbs (83.9 Kg).

Canada & USA ; 110-220 V, 60 Hz–30amp.

Europe, Asia, Australia; 230-250 V, 50 Hz–30 amps 5 KW*hr power consumption. (CSA) – (UL) and (CE).

Easy to hook up to your hot water supply, with a ½ ”inside diameter or hose. (1.27 cm)

It is recommended to connect to a water heater tank of 60 gallons and more (227 liters) set at 140 ° F (60 ° C) to allow the integrated water heater to perform a final rinse at + – 200 ° F with a minimum pressure of 50-60 psi. (3.65 Bar) The recommended drain: rigid pipe or with an inside diameter of 1 in, (2.54 cm).

High or Low water level switch (cut water consumption by half): ideal for new bottles when it requires a quick rinse.

Optional: High or Low water level switch (cut water consumption by half): ideal for new bottles when it requires a quick rinse.

Water level selector, cuts water consumption in half.

Digital HMI interface, to program cycle times and quantity of cleaning products.

Upper or lower wash arm.

Additional cleaning nozzles, rotating nozzles fixed under the diffuser and allow optimal cleaning.

Inspection According to standards CSA CE.

Bottle washer and dryer

Design to accelerate your washing process / Easy to integrated into a cleaning chain

Washing bottles and drying them properly is no easy task. It is complicated to wash a bottle regardless of its dimensions. It can therefore be difficult for some producers to have to wash their many bottles by hand, whether in the beverage sector, in laboratories, on farms, or in pharmaceuticals etc…. It is therefore of great importance for these producers to have to find equipment capable of carrying out all these steps which includes washing, rinsing, cleaning, disinfection. Finding equipment that can do all of this can be complicated, as few companies can make machines that can wash many bottles of any size and quickly.

A company comes into play here. Our company Aquatech-BM produces customizable equipment which combines all these stages, our bottle washers and dryers can allow these producers or others to save time and efficiency. It is clear that for laboratories for example where the container must have perfect hygiene, this will allow them to work in better conditions with perfectly clean containers. It goes without saying that our equipment has great potential for some producers who use containers that are difficult to wash without the aid of a suitable machine.