Table of Contents

Have you ever thought about the journey a beer keg or a cooler water bottle goes through before it reaches your favorite pub or home? From the moment they are emptied to when they are refilled, these large containers have a critical role to play in delivering beverages and essential resources to our everyday lives.

However, there’s a major problem lurking beneath the surface that many people overlook – the daunting task of washing and sterilizing these containers. It may seem like a straightforward process, but when you consider the size and complexity of these vessels, you’ll soon realize why washing them is no easy feat.

In industries where beer kegs, water tanks, and other large containers are utilized, cleanliness and hygiene are of utmost importance. It’s not just about making sure they look presentable; it’s about ensuring every nook and cranny is thoroughly cleaned and sterilized before reuse. Failing to do so can have dire consequences, potentially compromising the quality of the products and even posing a health risk to consumers. That’s why washing these large containers is a critical step in maintaining the integrity of the beverages or resources they hold.

Why You Should Not Clean Large Containers by Hand

When it comes to washing large containers, hand cleaning and other traditional cleaning methods may seem like the most efficient option. However, these outdated practices should be avoided at all costs. Hand cleaning is inefficient and ineffective and can leave surfaces unclean or even contaminated. It also requires a significant expenditure of both time and labor, which can be costly over time.

In addition to being inefficient, hand cleaning can also be dangerous. Depending on the size of the container, employees may be at risk of sustaining physical injuries while attempting to clean them. Furthermore, without proper training and safety equipment (such as goggles and gloves), they may even face potential hazards such as chemical exposure or inhalation of toxic fumes.

The Significance of Sterilization for Reusing Large Containers

For breweries, wineries, cideries, distilleries, and other beverage producers, reusing large containers like kegs is an essential way to save money and reduce waste. Proper sterilization is the key to ensuring that these containers stay clean and safe for use over the long haul.

Without a thorough sterilization process, bacteria and other contaminants can build up on the inside of containers and contaminate batches of the products. The result is lost time, product, and money.

Sterilization is also important for maintaining the quality of beverages that are put into kegs and other large containers. Without sterilization, the taste and flavor of these beverages can quickly degrade over time due to bacterial growth, leading to unhappy customers.

The Best Solution: Automated Container Washers

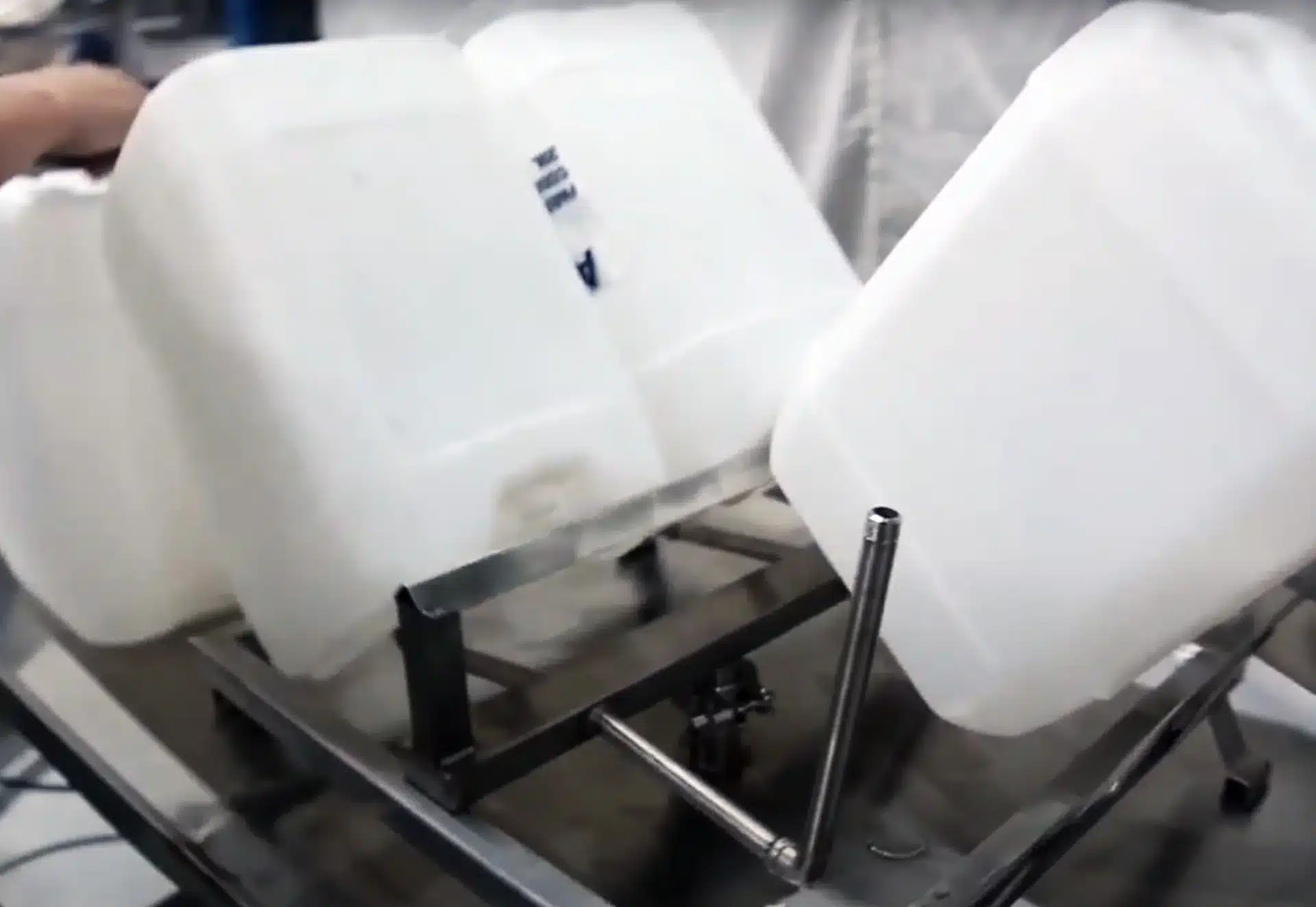

The best way to ensure that large containers are properly washed and sterilized is to use a specialized container washer. Investing in a keg cleaner or an industrial bucket washer, for instance, can help streamline the process of cleaning and sterilizing large containers.

Automated washers are designed to safely and efficiently clean containers of all shapes and sizes while also providing a safer environment for employees. They can even be programmed to use specific cleaning solutions or chemicals depending on the type of container and the contaminants present.

So, by providing an automated solution that eliminates the need for manual labor, these washers can help your business save time and money while simultaneously ensuring the safety of your employees.

Introducing Aquatech-BM Bottle Washers

Aquatech-BM Bottle Washers are top-of-the-line machines designed for thorough bottle and container cleaning for commercial and industrial applications. With their advanced technology and innovative features, they provide exceptional performance. These washers efficiently remove dirt, debris, labels, and other impurities from a wide range of bottles, containers, and kegs sizes using high-pressure water jets, cleaning agents, and mechanical action.

Aquatech-BM bottle washers also have specialized rinsing cycles to ensure complete cleanliness, leaving these containers spotless and ready for use. Additionally, their automated operation and programming make them ideal for busy industrial applications that require a reliable yet cost-effective cleaning solution.

The user-friendly interface allows operators to customize settings, ensuring consistent and precise results. Aquatech-BM Bottle Washers prioritize efficiency and sustainability, minimizing water and energy consumption. These durable machines require minimal maintenance and come with water recycling systems and energy-saving features.

With their cutting-edge technology and focus on cleanliness, Aquatech-BM Bottle Washers are essential for maintaining hygiene in bottle-based production processes.

Benefits of Using a Bottle Washer

Using a bottle washer offers several benefits for both commercial and industrial entities. Firstly, the multi-function bottle washer is equipped with programmable cycles, allowing for customized cleaning processes using the digital screen. It is designed to efficiently clean, rinse, wash, and sanitize small to medium-sized bottles. The user-friendly control interface also makes operation simple and hassle-free.

The Aquatech-BM bottle washer also features a hot water booster tank that can easily be connected to the existing hot water supply, ensuring optimal cleaning temperature. Additionally, the washer’s water level selector reduces water consumption by half, making it ideal for quick rinsing of new bottles.

For industrial-scale cleaning, an industrial container washer is available, capable of handling various container sizes. Its digital HMI interface allows the programming of cycle times and cleaning product quantities. Customization options are also available, ensuring the washer meets specific needs and requirements.

Furthermore, the multi-function bottle dryer is designed to speed up the drying process. It can handle different materials like glass, plastic, and aluminum. The dryer comes with interchangeable baskets to accommodate containers of different diameters, and the drying time and temperature are adjustable for maximum efficiency.

Contact Us Today For All Your Bottle Washing Needs

At Aquatech-BM, we understand the importance of cleanliness and hygiene in your business. That’s why we provide high-quality bottle, container, and tank washers that you can count on. Our team is committed to delivering top-notch solutions that meet your unique needs.

Contact us today for more information about our products and services. We look forward to helping you find the perfect bottle washer for your business.